The manufacturing sector is changing and evolving every day as technology moves forward and competition tightens.

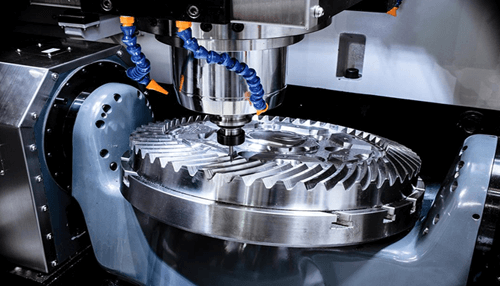

Some years ago, CNC machining was an experimental technique with minimal availability, but now things have changed drastically. Demand for high-quality CNC parts is continually rising, putting pressure on manufacturers to improve their overall business operations if they want to stay in the game.

This means that machining and milling companies must employ strategies to increase their efficiency. CNC machine shop today benefits significantly from the modernization of CNC machining tools.

They also need to find experienced CNC manufacturing machinists, which are getting harder and harder to find since the industry is growing more rapidly than the labor market. We all want to get the most out of our CNC machines, but no matter how well planned, constructed, and fitted they are, these tools are only as efficient as we allow them to be.

In other words, many manufacturing processes are possible, and some are more efficient than others. Here are the five most important strategies to improve CNC machining efficiency within your company.

Pay Close Attention To The Management Of Your CNC Machines

Holding your CNC machinery cost as low as possible and investing in a manufacturing tool management system is proven to be a profitable strategy. Consider a tool management system for this purpose, as it will help you monitor and manage your inventory. CNC machining service is a great way to reduce overstocking or understocking costs of your tool supply.

If you are manufacturing in the USA, you can find useful software for your CNC machine shop that will help you monitor efficiency, tool use, and procurement. A great feature of this software is critical purchase alerts since it will help you avoid expensive truck stops.

It is crucial to acknowledge that your output quantity isn’t the only thing that makes your business grow. Analyzing your customers’ type of services carefully and streamlining your overall business processes are also vital elements.

Extend The Life Of Your Machinery

Getting a high-pressure cooling system is a great way to extend the life of your machinery’s tools. If you can’t afford that at the moment, consider increasing the concentration on the existing one.

Examine your holder and the inserts regularly. This will help prevent costly breakdowns. Keep track of the number of materials that are being extracted. It would be worthwhile to upgrade the cnc stepper motor for better life. Experts in mechanical engineering strongly advise not to prolong extreme contact time with new materials. It is recommended to go for tougher insert grades of your choice during this process, which will serve you for a long time.

Some particular layers, such as aluminum oxide, allow you to keep your tool holder for a long time while increasing your tool and feed speeds’ longevity. Alternatively, investing in a cryogenic machine may be considered.

Improve Organization

Failure to coordinate correctly will lead to loss of money and a considerable waste of labor force. Tidy up your company’s workplace as much as possible, especially if it is the machining site in question. When you’re done with your job, you must plan and put stuff in order.

You need to ensure that you invest in quality shadow boards and tool draws like those used in manufacturing schools. In order to avoid misunderstanding, you can also improve the labeling scheme. You should maintain the cleanliness of your appliances and the floor because it can prove beneficial to your workforce health and your manufacturing operations.

CNC Programing Is Essential

One of the most critical tasks with CNC machining is CNC programming. CNC programming is a crucial element of the process that should continuously be improved. An accomplished programmer who knows how to construct good programming can cleverly use the inherent software, reduce the CNC system’s accumulated error, use the machine’s program, subroutine versatility, and help you improve your machining efficiency altogether.

A multi-part method of processing is typically used in the process of complex mold processing. If there are many similar types, you can use the relationship between the main program and the sub-program and repeatedly use the subroutine in the program until the machining is complete.

Incremental computing is a software function that only re-calculates outputs based on the collected data. You can also use incremental computers to write a program, but this can lead to a cumulative error when multi-segment programs are run continuously. It would be best to write a full program to reduce the CNC system’s accumulated error and ensure the processing’s consistency.

Human Resources Go Hand In Hand With Improving Efficiency

Cliches are most often true, and so is this one – the most valuable asset are your people. The more you invest in them, the more they create, improving your manufacturing facility’s overall effectiveness. Here’s what you can do to:

- Develop an apprenticeship program. Most CNC “shops” have developed apprenticeship programs within the enterprise, developing workers’ skills, and keeping them engaged.

- Employee evaluations. Providing workers with quarterly or annual review sheets can help them better understand where they stand in your organization. It also demonstrates that you care about them and take a proactive approach in their professional development.

- Create a magnetic culture. Businesses with good communities and satisfied workers have lower turnover, which could be the most incredible productivity multiplier of all in the long run.

Final Thoughts

Running a tight ship on the manufacturing floor will surely increase your CNC machining efficiency. You should have a broad approach and use different tactics and strategies, so pay attention to the essential elements discussed above: take care of your tools and equipment, organize everything, invest in technology and your workforce.