Industrial business owners must follow federal laws and regulations related to preventing occupational diseases. Employers are responsible for managing the health and safety of workers at all times. A failure to protect the workers leads to a violation of federal laws and could lead to a lawsuit for an occupational disease or worker-related injury. Employers who want to learn about how to improve health and safety in the workplace should review the 10 crucial hygienic principles for any industrial environment.

1. Hire an Industrial Hygienist

Hiring an industrial hygienist helps employers determine if there are any existing health or safety risks present in their work environment. The findings determine what improvements are necessary to protect workers. Employers who aren’t sure if risks are present need a hygiene assessment immediately.

2. Test and Evaluate Ergonomics

Testing and evaluating ergonomics determines if the workers are at risk of developing any injuries due to repetitive motion or stress on the body. Common conditions related to repetitive motion or stress include tendonitis, back injuries, and carpal tunnel syndrome.

Asbestos removal is a critical and highly regulated process aimed at safely eliminating asbestos-containing materials (ACMs) from buildings and structures to protect human health and the environment.

3. Evaluate Risks Related to Temperature

Evaluating risks related to temperature determine if the temperature in a building could lead to a heat stroke. It is vital for employers who have hotter-than-average properties to install fans or air conditioning units to cool the property and provide adequate water to their workers.

4. Test the Indoor Air Quality

Testing the indoor air quality lowers the risk of exposure to contaminants such as asbestos. The findings of the evaluations determine if the business owner needs to take action to protect their workers, like scheduling the removal of asbestos building materials.

5. Identify Any Radiation Levels

Identifying any radiation levels defines a profound risk to workers. Laser or ultraviolet radiation presents a risk to workers, such as severe burns. The risks could also include sterilization and several forms of cancer.

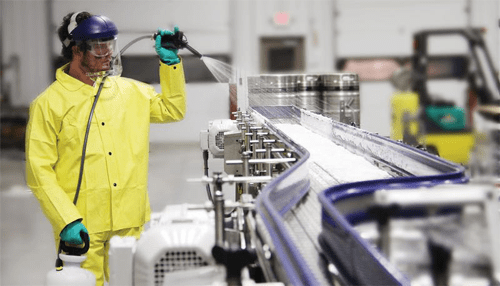

6. Assess the Chemical Exposure

Assessing chemical exposure defines if the workers are at risk of inhaling, ingesting, or absorbing harmful chemicals. The most common chemicals that are known to cause illnesses in the workplace are pesticides and gasoline.

7. Reviewing Possible Biological Hazards

Reviewing possible biological hazards determines if there is any chance of exposure to the hazards. Typically, medical staff are at the greatest risk of exposure to biological hazards. Blood, waste products, and biological secretions are the most hazardous.

8. Removing Hazards and Initiating Controls

Removing hazards and initiating controls helps companies reduce the risk of an occupational disease or injury. Initiating better controls and protocols helps companies monitor the workspace more proactively.

9. Testing Workers for Occupational Diseases

Testing workers for occupational diseases helps employers identify any injured workers who require full treatment for the occupational disease. By testing workers, it is possible to find the illness at an earlier and treatable stage. It could also lower the risk of a lawsuit for the company.

10. Completing OSHA Evaluations and Risk Assessments

Completing OSHA evaluations and risk assessments regularly help the company lower known risks to workers and maintain a safe work environment. It could also increase the odds of passing the OSHA inspections and avoiding penalties.

Industrial business owners must comply with federal regulations and laws pertaining to workplace safety. Occupational diseases and worker-related injuries are caused by a failure to monitor and control the industrial environment. Employers who follow crucial hygienic principles maintain a safe workplace and protect their workers properly.