On the hunt for the perfect PCB to add to your design? Thousands of products containing printed circuit boards are launched every year and the next one you launch could be the makings of your entrepreneurial career. Which one is right for you? One of the most common ones you will probably here about is the Rigid Flex PCB. Here are some of the advantages and disadvantages of choosing to use a rigid flex PCB, to help you decide if it is right for you.

1. Fewer Parts Needed

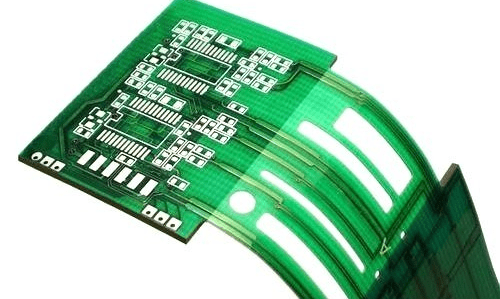

Traditional circuit boards needed a lot of components with a lot of connections. When you choose to use a flexible circuit board, you are choosing an option that does not need nearly so many interconnections. What is more, because it requires few connections, you can introduce a much more complex configuration all while maintaining the parts quota. It is an extremely important tool which you cannot neglect.

2. Lower Weights

Another advantage to having fewer parts is the weight reduction which comes with it. Since rigid flex PCBs are frequently used in many different items where weight becomes a necessary attribute – such as military or medicinal technologies – if weight is going to be a major problem for you then you should definitely look into incorporating this type of PCB. It is a pretty minor thing which can become quite the problem if not properly addressed.

3. Cost

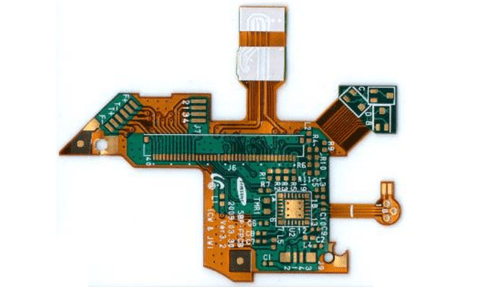

If you have a strict budget to adhere to, a rigid flex circuit board might not be for you. They are one of the pricier components on the market; sometimes even coming in more than the price of a standard rigid and flexible circuit board put together. They have many brilliant uses but you will have to truly ask yourself if it is a truly necessary component.

4. Difficult to Change

If, during the testing phase, you find yourself needing to make adjustments to the actual design, this can be extremely difficult to do with a rigid flex circuit board. You might need to return to the original drawing or the gerber programming to fix the issue. If this happens, you obviously need to spend more time and resources fixing the issue and potentially redoing the entire design. Therefore, you need to decide carefully whether you want to use a rigid flex printed circuit board. While there are many benefits to using one, there are also some significant disadvantages.

A rigid flex PCB is the same as any piece of equipment; it has both significant advantages and disadvantages which may influence whether or not you use it. Weigh up the pros and cons before you choose to use it. There may be an alternative out there which is much better for your budget and your overall designs. Don’t be afraid to take a little time to fully research your design before manufacturing a prototype; this stage will be just as important as any testing you could do. Before long, you will have the perfect PCB design to suit your project.