Introduction:

In recent years, the rise of 3D printing technology has extensively impacted multiple industries, drastically affecting architecture and engineering, in which its transformative abilities have been harnessed. Architects and engineers have seen an evolution in house design methodologies because of the modern programs of 3-D printing. This groundbreaking technology has no longer revolutionized the creative technique but has additionally optimized the construction stages, improving efficiency, precision, and customization in growing residential structures. This article delves into how these skilled experts leverage the prowess of 3-D printing to power innovation and simplify the problematic journey of bringing architectural visions to lifestyles in residential initiatives.

The Integration of 3D Printing in Architectural Design:

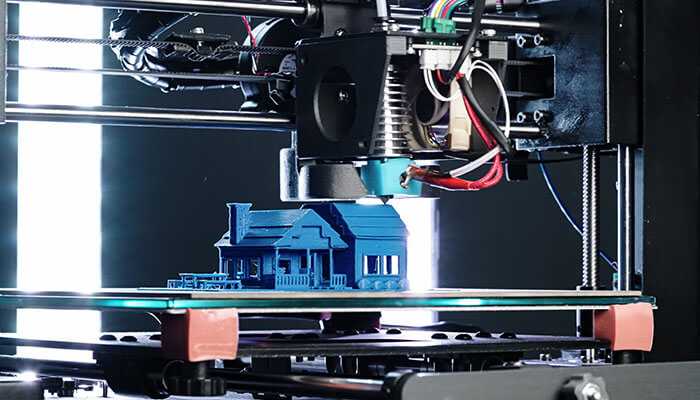

Traditionally, architects have relied on the specific design of guide drafting and the use of a computer-aided design (CAD) software program to visualize and meticulously plan problematic homes and systems. With the groundbreaking emergence of 3D printing technology in the architectural field, architects are now equipped with the advanced capability to quickly and completely rework their conceptual designs into concrete material models with a remarkable level of efficiency and precision.

This evolution permits architects to successfully bridge the distance between the virtual and physical worlds using translating intricate virtual blueprints into tangible prototypes, allowing them to gain valuable insights into the difficult interplay of spatial relationships, scale versions, and the nuanced aspects of shape that outline a structure’s aesthetic enchantment and practical integrity.

One of the primary advantages of integrating 3-D printing generation into architectural layout methods is the significant impact it has on streamlining and enhancing the creation of architectural models. By harnessing the competencies of 3-D printing, architects can considerably accelerate the development stage, taking into consideration quick changes and modifications to their designs. This quick development cycle, which could produce a couple of variations of a model in a remarkably quick time frame, not only quickens the design procedure but also creates a dynamic environment where architects can continuously refine and improve their standards.

Furthermore, the incorporation of 3-D printing technology into structures creates a variety of chances for architects to comprehend challenging and, particularly, custom-designed architectural features. Whether it is creating complex facades that intricately capture the soul of a structure or making sculptural components with exquisite detail, 3D printing is an effective technique that architects may use. Architects may exhibit their creative concepts with unprecedented precision and efficiency by combining modern software programs and complicated additive production techniques, redefining the boundaries of architectural design and construction.

The Role of 3D Printing in Structural Engineering:

In addition to architectural layout, 3-D printing is increasingly recognized for its pivotal position in advancing the sector of structural engineering, mainly in terms of enhancing the efficiency and performance of constructing additives and structures. Structural engineers Use the Power of 3D printing technology to supply a wide range of structural factors, including beams, columns, and trusses, that boast advanced power-to-weight ratios compared to standard manufacturing strategies. This technological advancement permits engineers to best-track the geometric shapes and material houses of these components, resulting in a full-size reduction of fabric wastage and universal production prices, all whilst upholding the utmost structural integrity of the final construction initiatives.

Furthermore, 3D printing technology empowers engineers to lay out and convey complicated designs that excel both in structural integrity and visual appeal. Through the utilization of computational layout tools and generative algorithms, engineers can fine-tune the shape and functionality of structural components to meet unique load demands and environmental elements. This comprehensive design method not only most effectively permits engineers to craft enduring and sustainable buildings but also guarantees their resilience over the years.

Moreover, the usage of 3-D printing extends its impact to the world of constructing envelopes and exterior systems, where good-sized advancements are being made. By merging parametric modeling strategies with digital fabrication tactics, engineers can create custom Exterior panels decorated with unique patterns and textures. These custom-designed panels now not only serve to enhance the aesthetic appeal of structures but also play a pivotal role in improving their thermal insulation and average power efficiency.

Case Studies: Real-World Applications of 3D Printed Houses:

Several innovative projects have demonstrated the enormous potential of 3D printing to transform the homebuilding industry. One remarkable incident that captured the attention of the business occurred in 2018 when ICON, a forward-thinking business, opened the doors to the first officially recognized 3-D printed home in the history of the United States. ICON’s Vulcan 3-D printing generation, a technological marvel, was put on full display when it painstakingly created a 350-square-foot residence in a mere twenty-four hours, creating a new standard for speed and performance in the building industry.

This enormous achievement not only successfully established the idea of employing 3-D printing to build more affordable and environmentally friendly homes, but it also inspired a global wave of creativity and ideas.

Moreover, in the Netherlands, across the ocean, a fantastic project by the name of Project Milestone has emerged to establish a series of environmentally friendly three-dimensional houses made of bio-based materials. This ambitious project is at the forefront of utilizing renewable resources like bioplastics and recyclable materials to build homes that are not only aesthetically pleasing but also have a carbon-neutral footprint. It is driven by a passion for environmental responsibility. Project Milestone, which was created by a team of distinguished architects, committed engineers, and forward-thinking material scientists, is the perfect example of how various disciplines can work together harmoniously to redefine the future of sustainable real estate through innovation and unwavering determination.

Future Outlook and Challenges:

While the potential of three-D printing in structure and engineering is exciting various challenging problems remain to be addressed. These challenges include technological limitations, including pace and scale, regulatory hurdles concerning protection standards and construction rules, in addition to material constraints in terms of energy and durability. Additionally, there’s an urgent need for extra collaboration and expertise-sharing among stakeholders, consisting of architects, engineers, fabric scientists, and creation experts, to together free up the overall ability of 3-D printing inside the creation industry.

Nevertheless, despite these limitations, the future of 3-D printing in-house design is undeniably bright and full of interesting opportunities. With continuous technological improvements and the increasing attractiveness of this progressive method, we can assume a revolution in architecture that is going beyond our cutting-edge knowledge. As those obstacles gradually diminish, architects and engineers will lead a brand new era of design creativity, sustainability, and efficiency in constructing production, in the long run reshaping how we perceive and interact with our constructed surroundings. By fully embracing the transformative strength of 3-D printing, the boundaries of architectural innovation are being pushed in the direction of a future where homes are not simply structures but dynamic expressions of human intellect and creativity.

Conclusion:

In conclusion, the groundbreaking impact of 3D printing technology on architecture and engineering is clear. This innovative tool has converted the conventional approach to designing homes by imparting exceptional advantages. From streamlining the prototyping process to improving structural performance, 3D printing empowers professionals to discover uncharted realms of creativity and productivity within the realm of residential construction. By embracing the skills of additive production, architects and engineers can craft eco-friendly, budget-friendly, and aesthetically beautiful residential structures that resonate with the ever-changing needs of modern-day society.

Looking beforehand, the seamless integration of 3D printing techniques into house design now not only guarantees a wave of clean thoughts but additionally heralds a paradigm shift towards sustainability and ahead-questioning practices inside the architectural panorama.