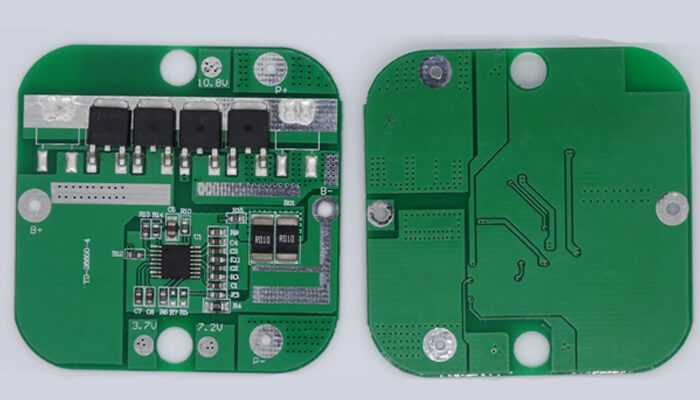

The lithium battery protection board is one of the core accessories of the lithium battery pack. It is closely related to the performance and safety of the lithium battery. At the same time, some smart lithium battery PCBs also have intelligent functions such as communication. As a lithium-ion batteries manufacturer with many years of R&D and production, Ufine Battery (Guangdong Ufine New Energy Co., Ltd) would like to share with you how to choose a lithium battery protection board.

What is the lithium battery protection board?

First, you must understand what a lithium battery protection board is. Many Ufine Battery customers also know little about these, and when talking about this, we must talk about lithium batteries.

Lithium batteries are used to store electrical energy, and the protective board is used to protect the battery. Without the protective board, the lithium battery will be unsafe, and there will be no way to form charge and discharge protection, temperature protection, battery protection, etc. Therefore, the choice of lithium battery, whether a cell or a protective board, is very important. Ufine Battery produces lithium battery protection with and without PCB. It can also customize various lithium polymer batteries, 18650 batteries, high-temperature lithium batteries, low-temperature lithium batteries, etc., with different voltages, capacities, and sizes according to customer needs.

Lithium battery protection board function

We all usually understand that PCB only protects the battery, so why are there two types of protection boards on the market? One kind of PCB is hardware, and the other is software.

Hardware board:

After a battery problem occurs, you can only check what kind of problem the battery has by disassembling the battery pack. This method is time-consuming and labor-intensive, and the battery needs to be returned to the factory for maintenance. Currently, the battery cannot be used, resulting in the product being unusable and causing economic losses.

Software board:

The software board can solve these problems remotely. Can the background software be used to check whether the battery pack needs to be returned to the factory for repair? Where does the problem occur? This will save a lot of labor and time costs.

How to choose the lithium battery protection board?

The selection of lithium battery PCB generally requires clearing a few key points to make the selection easy. Below, I will list a few key points. Then, you can easily buy a lithium battery protection board by following these key points.

1. Number of lithium battery PCB strings

The number of lithium battery BMS strings is based on the battery voltage, which can generally be determined by converting the rated voltage of the battery pack.

• Ternary battery string: The rated voltage of the battery is divided by 3.7 or 3.6 (the highest voltage is divided by 4.2V);

• Lithium iron battery: The rated voltage of the battery pack is divided by 3.2V (the maximum voltage is divided by 3.65v);

• Lithium titanate and sodium-ion batteries are calculated similarly by dividing their cell voltage.

2. PCB rated operating current

The rated current of the protection board is the upper limit of the current that the lithium battery protection board can withstand during normal operation. This parameter can be determined based on the following points:

1. Rated power of battery load. The current rating is determined by dividing the power rating by the voltage.

2. Peak current output by the battery. Generally, the larger the peak current and the longer the duration, the corresponding rated current also needs to be increased.

3. Battery pack rated capacity and rate. The product of capacity and rate is the upper limit of battery output capability. It is generally an important basis for selecting the rated current of the protection board.

Based on the above three parameters, follow the principle of choosing a large rather than a small one and leave a certain margin appropriately to determine the rated current of the PCB.

3. Communication type

To determine the communication parameters of the lithium battery protection board, it is necessary to determine the communication interface type and the contents of the communication protocol. Communication interfaces generally include RS485, RS232, CAN, UART, IIC, etc.

The communication protocol is generally the default protocol. If you want to customize the agreement, you need to make software modifications for a fee.

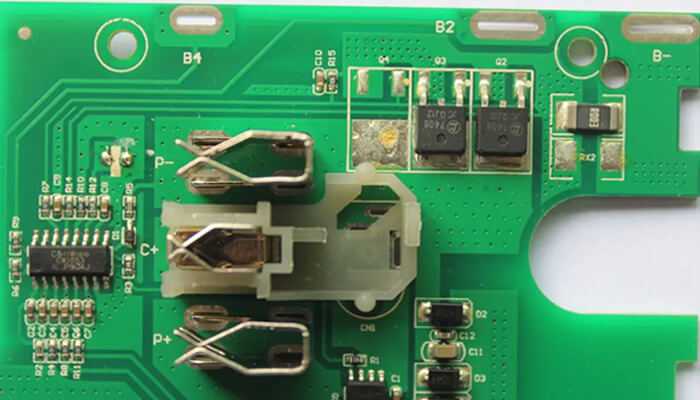

4. PCB size

Generally, the PCB size is related to its rated current. The larger the current, the larger the board size. This is also related to the material of the protective board (you cannot blindly pursue a small size; a smaller size means less material is used, and quality and function cannot be guaranteed).

Generally, standard mass-produced PCBs are mostly designed for a few specific high-volume products and cannot be suitable for all lithium batteries. Therefore, many new projects’ lithium battery protection board may need to be specially customized.

5. Application environment

Some lithium batteries must be used in various complex environments such as low temperature, high temperature, high altitude, or severe electromagnetic interference. At this time, the component selection and parameters of the lithium battery protection board need to be adjusted. This also needs to be determined clearly in advance. Otherwise, it is likely to affect the performance of subsequent products and, in serious cases, may lead to safety accidents.

6. Cost

Generally, lithium battery protection boards are divided into different levels according to their application characteristics: consumer-grade, industrial-grade, military-grade, etc. Corresponding product prices also vary greatly. Generally, consumer-grade products are relatively cheap, while industrial-grade and military-grade protective boards are more expensive. Their corresponding functions and accuracy are also significantly different, and they need to be selected according to the application characteristics of their projects.

If you can determine the above points, you will know to choose the lithium battery PCB that suits you.